Project Description

Metal grid, protective

Meshes made using sheet metal perforation technology for electronics, speakers, fireplaces and other decorative elements. If you need to mass-produce metal products, contact us, we have a full cycle of work from metal selection, to powder coating and packaging. We ship finished products throughout Ukraine and abroad.

Protective mesh for speaker system (acoustic protective mesh). Steel 1.5 mm

We produce parts and structures for Ukraine and Europe with delivery. Contact us to discuss your project.

Production of custom-made protective nets from metal based on Magnet production

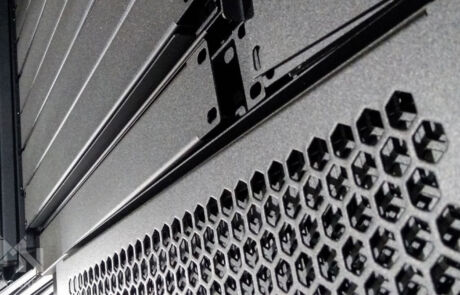

Examples of our work.

The grid performs several functions at once:

- Protection against mechanical influences – especially important for car audio systems, if animals are often transferred in the cabin or children drive;

- Enhance appearance - add the finishing touch and help to harmoniously fit the speaker system into the interior of a car or room through a variety of shapes, colors, the number of cells and their shapes, etc.;

- Increases the service life of the product. Reduces contamination of the internal filling, which extends the service life.

Features of the design and use of acoustic meshes

When choosing the design of a protective acoustic mesh, many users prefer easily removable models.. Speaker guards, offered by the company "MAGNET" are characterized by acoustic transparency and do not adversely affect sound waves. Thanks to the special shape of the mesh meshes, they optimally disperse sound, forming a stable radiation pattern, which can be used to distribute sound waves.

Depending on the shape of the model, the mesh can completely cover the front panel of the speaker system, changing her appearance. Or be shaped like speakers, coincide with them along the contour. Depending on the color and structure, this protection may, how to select a speaker system, and disguise it, making her invisible.

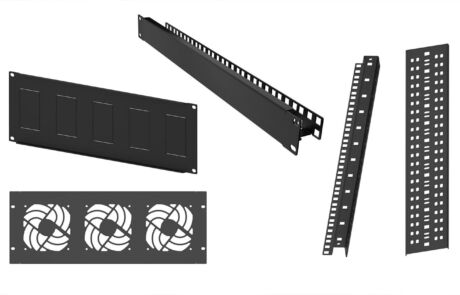

Technology for the production of protective nets

Sheet steel or metal alloys are used as the material for the manufacture of acoustic protective grids., with sufficient strength. Equipment, used in the production process, has a high degree of automation, which has a positive effect on the quality of the product..

In the production of acoustic meshes, the following production processes are used:

- Cutting a steel sheet - a machine is used for cnc laser cutting. It provides high dimensional accuracy and cutting cleanliness.. Eliminates the need for additional processing of the ends;

- Bending, stamping - as a rule, acoustic grids have curvilinear shapes. Various devices can be used for shaping: bending machines or presses;

- Perforation – for sheet metal punching, which ensures optimal acoustic transparency, CNC laser machine used. They provide a wide range of sizing options., shapes and locations of holes on the plane. A circle can act as holes, oval, hexagon, square or rectangle. Holes can be arranged in straight rows, offset or structured.

- Anti-corrosion protection – Powder coating is used to protect metal from rust.. This provides a high degree of resistance to external influences..

Thanks to the painstaking approach of MAGNET metalworking specialists, products are created of the highest quality.. We manufacture protective acoustic meshes of any complexity to order, according to your drawings.

ORDER A PROJECT CALCULATION

For quick calculation of the order value, upload drawings of finished parts and their flat pattern in DWG or DXF format using the form or send them to info@magnet.com.ua.

Along with the drawings, indicate the number of parts in your production, material type, his brand, material thickness, and the number of parts of each type.

Do not use special characters in the file name (quotes, brackets, dash), and symbols in Cyrillic.

Drawings must be straight, arcs and polylines. No splines allowed. Enter your contacts (e-mail, telephone), so that we can contact you.

Language

Language