Metalworking services

Creation of unique designs, complex mechanisms and parts of industrial equipment is impossible without metal processing. Modern technologies make it possible to produce a product of the required shape with given dimensions and physical characteristics..

Metalworking methods can be divided into several groups:

- Laser cutting.

- Bending.

- Milling work.

- Perforation.

- Drilling works.

- Welding.

Parts for various industries are made from metal alloys using automated equipment. Independent provision of production with metal structures is not always reasonable. Purchase and maintenance of units, hiring operators and their training entails additional costs. Optimal solution – production of parts to order. Today there are several categories of metal processing services available..

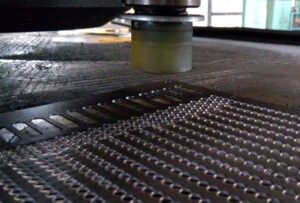

Laser cutting

Precise cutting of sheet steel, cast iron, aluminum and other metals is performed using a laser. The beam is generated by a special installation, focuses at the desired point and destroys the canvas in the cut zone. Laser cutting runs fast, accurate and contactless. Edges are smooth, no need for improvement. The method is effective in piece production of parts, production of small batches, creation of units of machine-building units, forged products. For laser cutting, solid-state type installations are used., gas and gas-dynamic units.

Metal bending

Metal bending is a workpiece deformation technology, as a result of which the sheet is bent. The method is suitable for the construction of window and door openings., facade finishing, roofing. Deformation with specified parameters is performed on bending machines. Sheet shape changes under pressure. Ultra-precise equipment allows you to bend the sheet, maintaining the integrity of the workpiece. Bending can be one-angle, multi-angle and radius (for making loops, clamps).

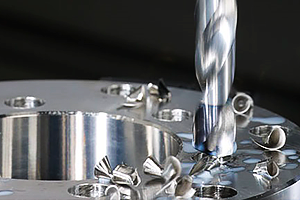

Milling work

Milling is a type of cutting. Processing a metal surface with a cutter is effective in cleaning planes, working with bulky parts, polishing, engraving, drawing patterns. Spheres of application of technology: mechanical engineering, jewelry production, architecture. The method is suitable for processing any metals and alloys. There are several types of milling: end, terminal, cylindrical, dentate. The choice of method is determined by the specific task.

Metal perforation

Even holes on a metal surface are made using special machines. For metal punching suitable for flat and sheet metal products. Processing allows you to make the material lighter while maintaining its initial characteristics.. Additional Perforation Benefits: elimination of slipperiness, enhancing aesthetics, simplification of assembly and dismantling processes. Hole making methods: stamping-punching, using a punch press or cluster, drilling, laser burning.

Drilling works

For making riveting, screw and bolt holes require locksmith operation – drilling metal. The technology is applicable to different grades of metal. Usually a high speed steel drill is used., but for metal processing, that are difficult to influence, carbide drill is used. This tool is suitable for drilling cast iron., of stainless steel. Holes may be blind, through, half-hearted. For certain tasks, deep openings or with a large diameter are made. When drilling holes for internal threads, GOST is used.

Metal welding

Welding technology is a connection of metal structures under the influence of high temperatures. Metal welding can be carried out by arc, light, gas, ultrasonic and other methods. The process requires strict adherence to technology. Any error can lead to a decrease in the characteristics of the seam. Undercuts not allowed, shortening or lengthening, abrupt transitions. Welding method performs different types of butt joints: back to back, with overlay or corner. Quality control is carried out according to GOST capillary, magnetic, radiation or ultrasonic methods. The seam is also checked for tightness..

ORDER A PROJECT CALCULATION

For quick calculation of the order value, upload drawings of finished parts and their flat pattern in DWG or DXF format using the form or send them to info@magnet.com.ua.

Along with the drawings, indicate the number of parts in your production, material type, his brand, material thickness, and the number of parts of each type.

Do not use special characters in the file name (quotes, brackets, dash), and symbols in Cyrillic.

Drawings must be straight, arcs and polylines. No splines allowed. Enter your contacts (e-mail, telephone), so that we can contact you.

Yes, company "MAGNET" provides metalworking services according to your drawings, and also we develop projects at your request. Yes, we carry out high-precision laser cutting of metal on CNC machines. We work with all types and alloys, such materials, as: steel, aluminum, brass, bronze, stainless steel. If you have any questions, call: +38 (098) 521 37 41, +38 (067) 466 60 07 and Our experts will help you to solve the assigned tasks.Frequently asked Questions:

Do we carry out metalworking according to customer's drawings?

Do you provide laser metal processing services?

What materials do you work with?

How can I contact you?

Language

Language