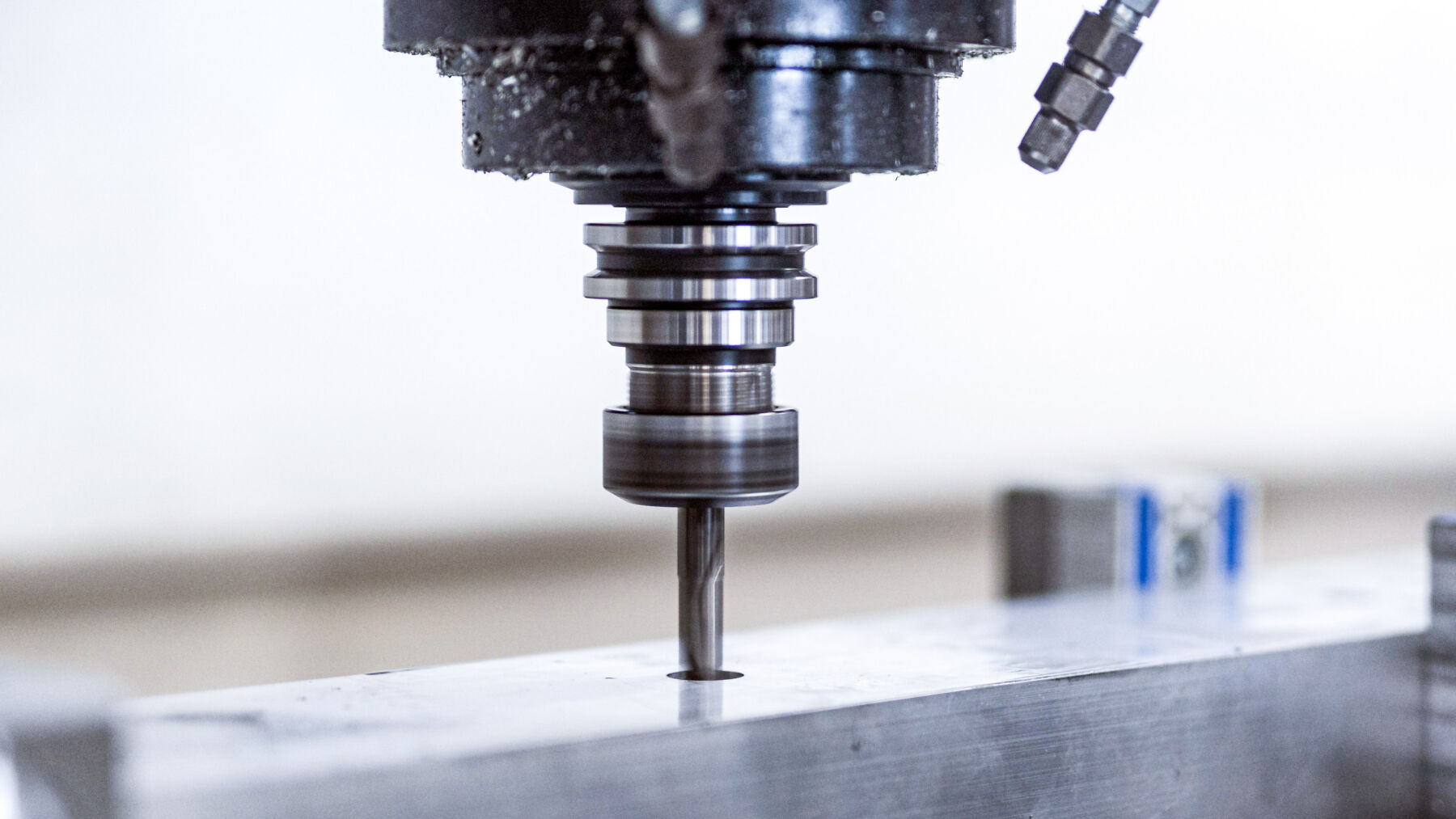

Milling work

We carry out milling metal processing with surgical precision and minimal material consumption.

Milling work on metal

Metalworking – this is a process associated with the need to process parts with high precision. Among the most requested processing options metal products – CNC milling. The name is based on the name of the main working cutting tool - cutters. The latter are rigidly attached to the machine shaft and are of various types., they are equipped with cutting teeth, whose edges are in periodic contact with the processed surface.

An individual calculation is carried out for each order.

Timing: from 1 of the day (depending on the volume and complexity of the order)

Materials (edit): individually approved.

The cost metal milling work depends on:

- the complexity of the work performed;

- circulation of the party;

- type of metal;

- volumes of other types machining.

Delivery: we deliver all over Ukraine

Why you need to order milling work from us?

Advantages of milling work on CNC machines at MAGNET

- We carry out work on the processing or manufacture of parts on CNC machines with high precision.

Significant cost reduction for design.

We process materials and alloys high strength.

Probability mistakes and marriage using CNC equipment for any metal products.

Powder coating of metal products provides a high quality coating high repeatability.

We make products with a low degree of roughness.

Received details do not require additional processing.

Orders are being fulfilled in a timely manner.

Details possible any complexity.

Milling works are performed according to the technical documentation of the customer. for any metal products. Powder coating of metal products provides a high quality coating. High accuracy of work and compliance with metal processing orders are guaranteed.

Types of milling:

End - used for processing large surfaces: flat and stepped. The cutting tool has a number of teeth 1…3 and more, depends on the type of work – cut, sample, roughing or semi-finishing. Parts of complex shape are made with a milling cutter with a spherical end face.

Terminal - used for processing planes, grooves, ledges. Use tools: ordinary and keyway cutters with tapered and cylindrical shank, roughing cutters with sharpened teeth and occipital, with carbide teeth for T-slots, segment keys.

Shaped - used to create complex geometric shapes, as well as profiles. Worms are made, Gears.

Peripheral - for cutting complex grooves and power milling.

3D — for three-dimensional processing of overall parts

Types of milled surfaces:

vertical;

horizontal;

oblique;

- shaped;

ledges and grooves of various profiles

three-dimensional

Our CNC equipment:

See also:

Milling metal processing is carried out in the following main options

- drilling, boring holes, threading - operations are performed with high precision. for any metal products, as well as taps and countersinks;

- thread milling - special processing of spiral surface variants with end, disk, comb cutters;

- Cutting and cutting - operations to divide materials into parts of fragments and remove excess from the edges. Powder coating of metal products provides a high quality coating;

- Gear milling and slotting - splined shafts processing, gears and wheels, including worm, helical, as well as straight-toothed, tapered, cylindrical. Use disk, worm, as well as profile and groove cutters.

ORDER A PROJECT CALCULATION

For quick calculation of the order value, upload drawings of finished parts and their flat pattern in DWG or DXF format using the form or send them to info@magnet.com.ua.

Along with the drawings, indicate the number of parts in your production, material type, his brand, material thickness, and the number of parts of each type.

Do not use special characters in the file name (quotes, brackets, dash), and symbols in Cyrillic.

Drawings must be straight, arcs and polylines. No splines allowed. Enter your contacts (e-mail, telephone), so that we can contact you.

Language

Language